Producing precisely graded limestone aggregate in the 20–40mm range represents a critical process in construction material manufacturing, serving as the foundational component for everything from structural concrete to road base applications. This specific size fraction provides the optimal balance between interlock strength and workability that modern engineering projects demand. Achieving consistent product specifications requires more than simple crushing—it demands a sophisticated understanding of fragmentation mechanics and equipment capabilities.

The selection of appropriate crushing machinery directly influences aggregate quality, production efficiency, and operational economics. When sourcing equipment, many global contractors consider manufacturers like China AIMIX Group, which offers specialized crushing solutions designed for precise aggregate production. The difference between acceptable and exceptional aggregate often lies in the nuanced relationship between limestone crusher machine configuration, material characteristics, and process control—a combination that separates basic rock reduction from precision aggregate manufacturing.

Crusher Selection for Optimal Size Reduction

Jaw Crushers for Primary Reduction

Initial Size Reduction Parameters

Primary crushing establishes the foundation for final product quality. Heavy-duty jaw crushers from manufacturers like AIMIX effectively reduce quarry-run limestone to 150-200mm fragments, creating optimal feed material for secondary crushing stages. Modern designs feature hydraulic adjustment systems that maintain consistent discharge settings despite wear, ensuring uniform feed size to downstream processes.

Throughput and Capacity Considerations

Select primary crushers with 20-30% excess capacity relative to nominal production requirements. This overhead accommodates natural material variability and prevents bottlenecks that could compromise the entire crushing circuit. AIMIX jaw crushers incorporate advanced kinematics that maximize capacity while minimizing energy consumption per ton—critical factors for profitable aggregate operations.

Secondary Crushing for Precision Grading

Cone Crushers for Cubic Particle Shape

Interparticle Crushing Advantages

Secondary cone crushers excel at producing the cubical particle geometry essential for high-performance 20–40mm aggregate. AIMIX hydraulic cone crushers utilize interparticle crushing principles where rock fractures against rock rather than metal surfaces, enhancing product shape while reducing wear costs. Advanced chamber designs and eccentric throw configurations optimize reduction ratios for limestone-specific characteristics.

Closed-Side Setting Optimization

Precise control of closed-side settings determines final product size distribution. Modern aggregate crushers feature remote adjustment capabilities that allow operators to fine-tune output without stopping production. AIMIX systems incorporate automatic setting regulation that compensates for wear in real-time, maintaining consistent product grading throughout liner lifecycles.

Screening and Process Control Systems

Particle Separation Efficiency

Multi-Deck Screening Technology

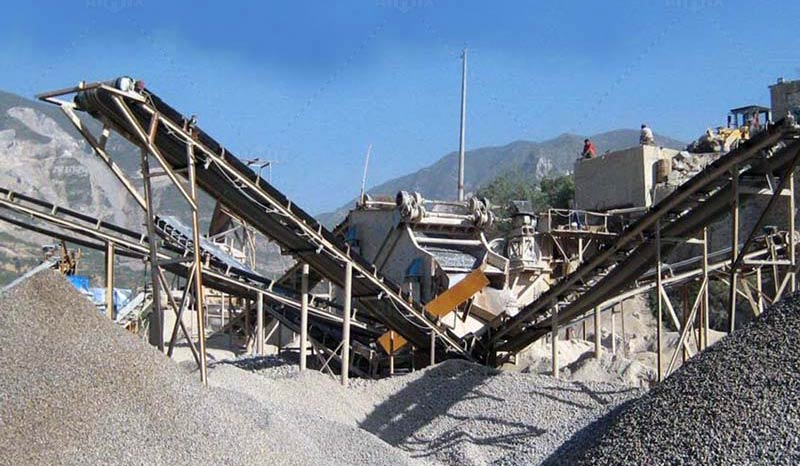

High-efficiency vibrating screens separate crushed material into precisely defined fractions. Three-deck screens typically route oversize material back to crushers, direct 20–40mm product to storage, and channel undersize to separate processing streams. AIMIX screening systems incorporate adjustable amplitude and frequency controls that optimize separation efficiency for varying material conditions.

Automated Circuit Control

Modern crushing plants utilize integrated process control systems that monitor and adjust operations in real-time. These systems track power draw, material levels, and product gradation, automatically making adjustments to maintain target specifications. When considering equipment from international suppliers like China AIMIX Group, ensure control systems support local language interfaces and remote monitoring capabilities.

Quality Assurance and Operational Efficiency

Gradation Consistency Maintenance

Automated Sampling and Analysis

Continuous product monitoring ensures consistent quality compliance with project specifications. Modern stone crusher plants incorporate automated sampling systems that extract material at predetermined intervals for size analysis. This data feeds back to crusher control systems, enabling real-time adjustments to maintain the target 20–40mm grading envelope.

Wear Part Management Strategies

Implement predictive wear monitoring for crusher liners and screen meshes. AIMIX crushers feature wear detection technology that alerts operators when components approach replacement thresholds. This proactive approach prevents unexpected downtime and maintains product consistency by addressing wear before it affects output quality.

Producing precisely graded 20–40mm limestone aggregate requires a systematic approach to crushing circuit design and operation. The right combination of primary and secondary crushing equipment, paired with efficient screening and process control, transforms raw limestone into high-value construction material. When selecting machinery, consider manufacturers like China AIMIX Group that offer complete crushing solutions backed by technical support and wear part availability. By understanding the interplay between equipment selection, process control, and material characteristics, producers can consistently achieve the exact aggregate specifications that modern construction projects demand.