Aggregate Crusher Plants: Key Raw Materials and Their Importance in Construction

The skeletal framework of our modern world, from the humblest sidewalk to the most soaring skyscraper, relies upon a deceptively simple material: aggregate. Produced through the meticulous processing of natural rock within aggregate crusher plants, this material forms the essential bedrock of the construction industry. The aggregate crusher plant is far more than simple rock breakers; they are sophisticated facilities engineered to transform raw, quarried stone into precisely graded, foundational components. The quality, type, and properties of the raw materials fed into these crushers are not merely a matter of operational convenience. They are the primary determinants of the final product's performance, influencing everything from the compressive strength of concrete to the longevity of a roadbed. Understanding this journey from geological formation to construction application reveals the profound significance of these unassuming materials.

The Primary Feedstock: A Geological Primer for Crusher Plants

The selection of raw material is the first and most critical decision in the aggregate production chain. The geological characteristics of the source rock dictate the entire crushing process and the suitability of the final product for its intended use.

Igneous Rock: The Bedrock of Strength and Durability

Formed from the cooling and solidification of magma or lava, igneous rocks are renowned for their density and hardness. Granite and basalt are the most common examples fed into crusher plants. Their interlocking crystalline structure grants them exceptional compressive strength and high resistance to abrasion and weathering. This makes them the quintessential choice for high-stress applications. You will find igneous aggregates as the backbone of heavy-duty concrete for dams and high-rise buildings, and as the durable surface course for high-traffic asphalt roads. Their inherent toughness, however, necessitates robust primary crushers and results in higher wear on crushing components.

Sedimentary Rock: The Versatile and Accessible Workhorse

This category encompasses rocks formed by the deposition and cementation of mineral and organic particles over millennia. Limestone and sandstone are the predominant sedimentary rocks used for aggregate. Generally softer and more porous than their igneous counterparts, they are far easier to crush and process, leading to higher production rates and reduced wear on the stone crusher plant. Limestone, in particular, is immensely versatile. It serves as a key raw material for cement manufacture and is a premier choice for base layers in road construction, concrete production, and even agricultural lime. Its widespread availability makes it an economically attractive option for a multitude of projects.

Metamorphic Rock: The Transformed and Resilient Contributor

Metamorphic rocks are igneous or sedimentary rocks that have been transformed by intense heat and pressure within the earth's crust. This process, known as metamorphism, alters their mineral composition and structure. Quartzite, the metamorphosed form of sandstone, becomes exceptionally hard and durable. Crushed slate finds a niche in specialized applications such as roofing granules and fine aggregates. While often less common than the other two types, metamorphic aggregates offer unique properties that can be leveraged for specific engineering requirements where their particular blend of hardness and foliation is advantageous.

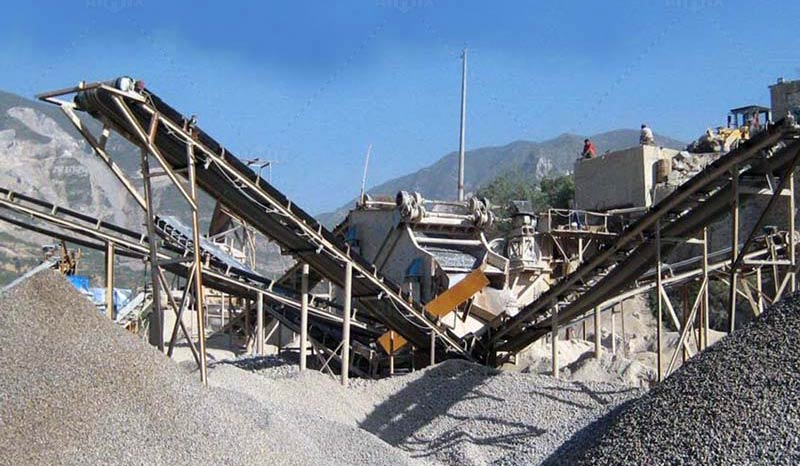

From Quarry Face to Precision-Graded Product

The transformation of massive bedrock into construction-grade aggregate is a systematic and multi-stage endeavor within the crusher plant. Each stage is designed to progressively reduce the material's size and sort it into specific, valuable fractions.

The Primary Crushing Stage: The Initial Reduction

This is where the first significant size reduction occurs. Large, blasted rock from the quarry face, sometimes measuring several feet across, is fed into a primary crusher. Jaw crushers and gyratory crushers are the workhorses of this stage, using immense mechanical force to compress and break the rock into smaller, more manageable pieces, typically reducing it to a size of 6 to 10 inches.

The Secondary and Tertiary Crushing Stages: Refining the Product

The material from the primary crusher is then conveyed to secondary crushers, such as cone crushers or impact crushers. Here, the rock is broken down further, shaping the particles and producing a wider range of sizes. For the highest specification products, a tertiary crushing stage may be employed. This final crushing phase is crucial for creating the finely graded, cubical-shaped aggregate prized for high-performance asphalt and concrete mixes, as it minimizes flaky or elongated particles that can compromise integrity.

The Screening and Washing Process: Achieving Specification

Crushing is only half the story. Screening is the critical process of separating the crushed material into different size categories, or "fractions," using a series of vibrating screens with different-sized meshes. This ensures that the final product meets precise project specifications, from large riprap for erosion control to fine sands. Washing may also be incorporated to remove clay, silt, and other deleterious materials, enhancing the aggregate's purity and ensuring a strong bond with cement in concrete.

The Indispensable Role of Quality Aggregate in Built Structures

The output from an aggregate crusher plant is far from a generic commodity. Its quality directly dictates the performance, safety, and longevity of the structures it helps to build.

In concrete, aggregate acts as a skeletal filler, comprising 60-80% of the mix's volume. It provides dimensional stability and vastly reduces the amount of cement paste required, which is both an economic and an environmental imperative. High-quality, clean, and well-graded aggregate produced by rock crushing plant is fundamental to achieving the design strength and durability of the concrete. Poor aggregate, contaminated with clay or organic matter, can lead to premature cracking, spalling, and structural failure.

In road construction, aggregates form the very foundation of the pavement structure. A strong, well-compacted aggregate base course distributes traffic loads and prevents the underlying soil from shifting. The surface course, whether asphalt or concrete, relies on high-quality aggregate for skid resistance and to withstand the relentless punishment of traffic and weather. The entire integrity of the transportation network is, quite literally, paved on a foundation of carefully processed aggregate. The silent, consistent performance of these crushed rocks is a testament to their irreplaceable role in shaping our constructed environment.