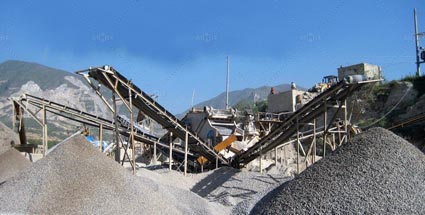

Let's settle a long-standing debate right now: producing high-quality, consistently sized limestone aggregate is not an art form shrouded in mystery; it's a precise science that demands a systematic, engineered approach. The difference between a profitable, efficient operation and a chaotic, wasteful one lies entirely in the methodology. Simply feeding rock into a rock crusher machine and hoping for the best is a recipe for inconsistent product, premature wear, and lost revenue. The 5-25mm aggregate range is the absolute workhorse of the construction industry, essential for everything from high-strength concrete to road base and drainage applications. Achieving this specific, valuable gradation requires more than just a single machine—it requires a deliberate, multi-stage crushing circuit designed for progressive reduction and meticulous classification. We're going to break down this process, step-by-step, and prove why anything less than this systematic approach is a direct compromise on your bottom line.

The Primary Breakdown: Establishing the Foundation with a Jaw Crusher

The entire process begins with the primary crushing stage, where raw, blasted limestone is transformed into a manageable feedstock. This is not a stage for subtlety; it is about applying immense, raw power to effect a coarse reduction.

The Unmatched Power of Compression Crushing

For primary crushing, the jaw crusher is the undisputed champion. Its operating principle is one of magnificent simplicity and brute force: a massive, fixed jaw plate acts as an anvil while a moving jaw plate pivots in a rhythmic, compressive motion. This action literally squeezes the large limestone boulders until they fracture along their natural cleavage lines. The key outcome of this stage is not to achieve the final 5-25mm product, but to create a uniform, intermediate product, typically in the range of 150mm to 250mm. This first reduction is critical because it establishes a consistent feed size for the subsequent, more precise secondary crushers. A well-set jaw crusher machine is the bedrock of the entire operation, and neglecting its setup—the correct closed-side setting (CSS) and optimal eccentric shaft speed—guarantees downstream inefficiency.

Vibrating Grizzlies and the Prelude to Precision

Before material even reaches the jaw crusher, a vibrating grizzly feeder performs a crucial pre-sorting function. This robust grid of steel bars allows smaller, sub-150mm material and fines to bypass the crusher entirely, falling through the gaps. This "scalping" process is a masterstroke of operational economy. It prevents the unnecessary processing of already suitably sized material, which would only create more fines and consume extra energy. It also protects the jaw crusher from being choked with fine, abrasive material that accelerates wear on the liners. This initial act of separation is the first hint of the precision to come, ensuring the primary crusher focuses its energy exclusively on the oversized boulders that truly require its attention.

The Secondary Refinement: Shaping and Sizing with an Impact Crusher

Once the limestone has been coarsely reduced by the jaw crusher, it enters the most critical phase of the entire circuit: secondary crushing. This is where the cubical, well-graded 5-25mm aggregate is truly born.

The Impact Crusher's Cubical Alchemy

For producing a high-quality, cubical product, the impact crusher is the superior choice over a cone crusher in many limestone applications. Its operating principle is one of violent, high-velocity impact. Material is fed into a rapidly spinning rotor equipped with sturdy hammers or blow bars, which hurle the rock against solid impact aprons or anvils. This action fractures the stone along its weakest points, naturally creating a more cubical particle shape—a characteristic highly prized for concrete strength and workability. The cubical nature of the output is a direct result of this impact-breaking action, which is far more effective at producing the desired shape than the inter-particle attrition common in compression-based crushers.

Controlling the Final Product

The final size of the aggregate exiting the impact crusher is precisely controlled by two key variables: the rotor speed and the gap setting between the rotor and the impact aprons. A higher rotor speed and a smaller gap will result in a finer product. This is the stage where the operator has direct, dynamic control over the product gradation, allowing for fine-tuning to hit the exact 5-25mm specification. The material produced at this stage is a mixture of sizes, from fine dust to pieces that may still be slightly oversized. It is now ready for its final, defining journey: classification.

The Final Classification: The Screening Process That Defines Quality

Crushing alone is insufficient. The final, non-negotiable step that separates an amateur operation from a professional one is the screening process. This is where the mixed-sized material from the secondary crusher is sorted into its final, saleable fractions.

The Vibrating Screen as the Ultimate Arbiter

The heart of this stage is the multi-deck vibrating screen. This machine is essentially a series of stacked sieves, each with progressively smaller mesh openings. The top deck typically has the largest openings, designed to scalp off any remaining oversized material (e.g., +25mm). This oversize is not waste; it is strategically recirculated via a closed-circuit conveyor system back into the impact limestone crusher machine for further reduction. The middle deck is calibrated with openings around 5mm, allowing the prized 5-25mm product to be retained on its surface while allowing smaller particles to fall through. This is your final, in-spec product, ready for stockpiling.

Closing the Loop and Maximizing Yield

The material that passes through the final screen—the sub-5mm material—is your crusher dust or fine aggregate. This, too, is a valuable product with its own market. The true genius of a well-designed circuit lies in this closed-loop configuration. By automatically recirculating oversize material, the system ensures that 100% of the feedstock is eventually processed into a saleable product. There is no "waste," only different product grades. This meticulous, step-by-step approach—from primary compression to secondary impact shaping and final screening—is the only way to reliably, efficiently, and profitably produce the high-demand 5-25mm limestone aggregate that builds our world. To skip a step is to leave money on the table and compromise on quality.