Limestone is one of the most versatile and widely used minerals in various industries, from construction to agriculture. Its transformation into powder form is essential for many applications, including cement production, soil amendment, and filler material in various products. This blog explores the critical equipment used for crushing and grinding limestone, highlighting their significance in the processing industry.

The Importance of Limestone Powder

Limestone powder serves multiple purposes across different sectors. In construction, it is a key ingredient in cement and concrete, providing strength and durability. In agriculture, limestone powder is used to improve soil quality by neutralizing acidity and providing essential nutrients. Additionally, it acts as a filler in products such as paint, rubber, and plastics, enhancing their properties.

The demand for high-quality limestone powder has increased, making efficient crushing and grinding processes crucial. Properly processed limestone not only improves product quality but also ensures compliance with industry standards. Therefore, investing in the right equipment for crushing and grinding is vital for maximizing productivity and profitability.

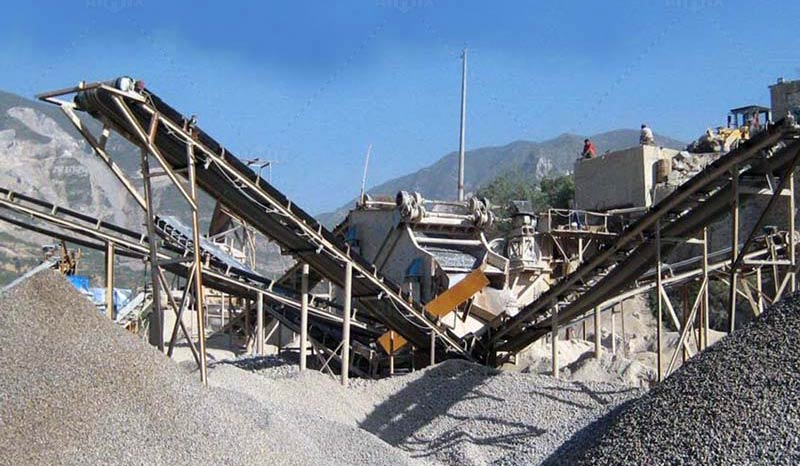

Key Equipment for Crushing Limestone

The first step in transforming limestone into powder is the crushing process. Several types of crusher machines are used to reduce the size of limestone, each with its unique features and benefits:

- Jaw Crushers: Ideal for primary crushing, jaw crushers use a compressive force to break large limestone blocks into smaller pieces. They are known for their durability and efficiency.

- Impact Crushers: These crushers utilize high-speed impact to crush limestone. They are particularly effective for producing fine materials and can handle softer materials efficiently.

- Hammer Mills: Hammer mills are versatile machines that crush limestone through high-speed rotating hammers. They are suitable for both primary and secondary crushing, making them a popular choice in the industry.

Choosing the right type of crusher depends on the desired particle size and the specific application requirements. Each type of crusher offers unique advantages that can enhance the overall efficiency of the crushing process.

Grinding Equipment: Turning Crushed Limestone into Powder

Once limestone is crushed to the desired size, the next step is grinding. This process further reduces particle size and transforms the material into fine powder. Various grinding equipment is available, including:

- Ball Mills: Ball mills are widely used for grinding limestone into a fine powder. They consist of a rotating cylinder filled with steel balls that grind the material as they collide with it. This method is effective for producing very fine powders.

- Raymond Mills: Raymond mills are another popular choice for grinding limestone. They use a combination of compression, grinding, and air classification to produce fine powders efficiently.

- Vertical Roller Mills: These mills utilize a rotating table and grinding rollers to crush and grind limestone. They are known for their energy efficiency and ability to handle large volumes of material.

When selecting grinding equipment, factors such as required particle size, production capacity, and energy efficiency should be considered to ensure optimal performance.

Quality Control and Optimization in Limestone Processing

Implementing quality control measures throughout the crushing and grinding processes is essential to achieve consistent product quality. Regular maintenance of equipment, monitoring of particle size distribution, and adherence to industry standards are crucial for success.

Additionally, optimizing the crushing and grinding processes can lead to significant cost savings. This can be achieved through:

- Process Automation: Automating the crushing and grinding processes can enhance efficiency, reduce labor costs, and minimize human error.

- Regular Maintenance: Scheduling routine maintenance can prevent equipment breakdowns and ensure consistent performance.

- Data Monitoring: Utilizing data analytics to monitor production metrics can help identify areas for improvement and optimize operational efficiency.

Conclusion

The transformation of limestone into powder is a critical process that requires the right equipment for crushing and grinding. Understanding the various types of limestone crushers and grinders available, as well as implementing quality control measures, is essential for maximizing productivity and profitability in limestone processing. As industries continue to demand high-quality limestone powder, investing in efficient equipment and optimizing processes will be key to success in this competitive market.